About Rice fortification

- Fortification is the process of adding Fortified Rice Kernels (FRK), containing FSSAI-prescribed micronutrients (Iron, Folic Acid, Vitamin B12) to normal Rice in a ratio of 1:100 (Mixing 1 Kg of FRK with 100 Kg custom milled rice).

- Fortified rice is nearly identical to traditional rice in aroma, taste, and texture. This process is done in the rice mills at the time of milling of rice.

- It is a cost-effective, culturally appropriate strategy to address micronutrient deficiency in countries with high per capita rice consumption.

Process of Rice Fortification

Rice Fortification is a 2-step process – (1) Production of Fortified Rice Kernels (FRK) (2) Blending of rice with FRK

Processes used for rice is fortification

- Various technologies, such as coating, dusting, and ‘extrusion’, are available to add micronutrients to regular rice.

- Adding micronutrient technology involves the production of Fortified Rice Kernels (FRKs) from a mixture using an ‘extruder’ machine. It is considered to be the best technology in India.

- Dry rice flour is mixed with a premix of micronutrients and water is added to this mixture, which is then passed through a twin-screw extruder with heating zones.

- Kernels similar in shape and size to rice are produced, which must “resemble the normal milled rice as closely as possible”.

- The kernels are dried, cooled, and packaged. FRK has a shelf life of at least 12 months.

- The kernels are blended with regular rice to produce fortified rice. Under the Ministry’s guidelines, 10 g of FRK must be blended with 1 kg of regular rice.

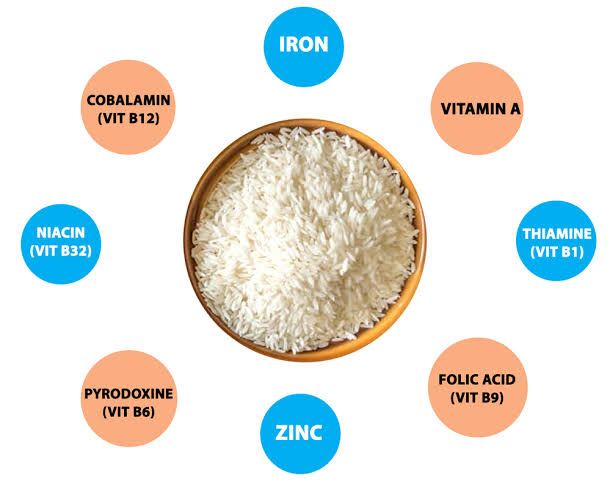

Nutrients of Fortified Rice

According to FSSAI norms, 1 kg of fortified rice will contain the following: iron (28 mg-42.5 mg), folic acid (75-125 micrograms), and vitamin B-12 (0.75-1.25 microgram).

Also read,